How to Prevent Arc Flash Hazards

By Lee Marchessault - Published on June 14, 2018 7:42 pm

There are approximately 20,000 arc flash hospitalizations every year in this country (IEEE). These incidences often cause debilitating burns which are extremely painful and require extended hospital stays often with profoundly negative affects on the lives of the worker’s and their families. Many of these injuries may be avoided or greatly reduced if proper assessments and work methods are utilized.

This entry is one of a series all about Arc Flash Hazards, how to assess them, and how they can be prevented. If you have any questions or would like to schedule an analysis, call the professionals at Workplace Safety Solutions at (802) 288-9441.

Can we prevent arc flash hazards?

Arc flashes are caused by an unplanned event that is related to failed equipment or foreign objects causing a short circuit between a grounding system and an ungrounded energized part, or between two or three ungrounded phases. This may include switches or breakers not operating properly, non-insulated tools placed or left across electrical parts, grounds left in place or other objects like mice, bolts, cobwebs, combustible dust, or other conductive apparatus inadvertently falling into electrical parts. Foremost is recognizing that there may be a hazard. This requires that a trained worker capable of understanding the construction and operation of the equipment perform an assessment before starting work on the equipment.

How can we mitigate or reduce the arc flash hazards.

A full arc flash analysis will state methods to reduce the arc flash hazard. The incident energy level from an arc flash is directly proportional to clearing time of the protective device, so recommendations may include changing breaker settings, installing different or new upstream fuses or installing arc flash relays. These changes will all lower the clearing time. Also, replacing transformers with lower impedance may lower the arc flash level, however consideration should be given to increased fault current creating other problems with overdutied panels.

Other methods to mitigate the exposure to employees include extending the distance from the exposed or operating parts by extending operating rods, or remote switching devices.

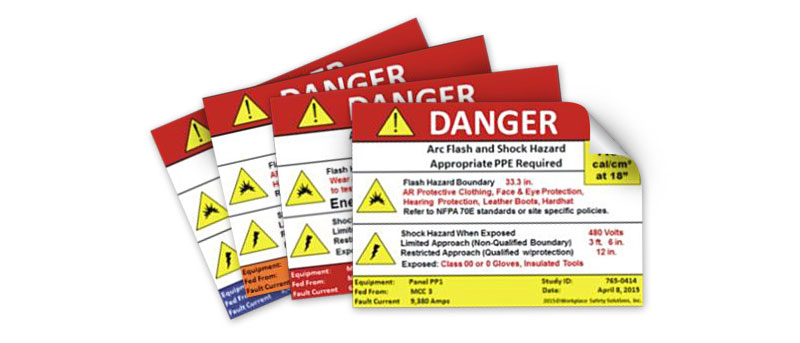

Lastly, PPE is required to protect employees from hazardous arc flash levels. Protective clothing systems are based on the arc flash hazard level in cal/cm² at working distance of 18” of the exposed part. If the arc flash PPE is at a proper level, the employee should not receive a second degree burn. For hazards assessed at greater than 40 cal/cm² equipment must be de-energized. The arc blast at higher levels may break bones so a suit rated higher would not protect from this injury.

Categorised in: Arc Flash, Blog, Consultant, Workplace Safety